Distillation is the most widely used method for separating liquids from liquids in industrial operations. It involves heating a mixture or blend to a specified temperature set point to exploit differences in relative volatility. As temperature rises, substances with lower boiling points are vaporized, while less volatile substances remain in liquid form.

This process occurs in a distillation column. A number of different column types, such as vacuum, plate, cryogenic, reactive and packed bed, can be found throughout process industry today. Packed bed columns are one of the widely used designs and combine the functions of absorption with distillation.

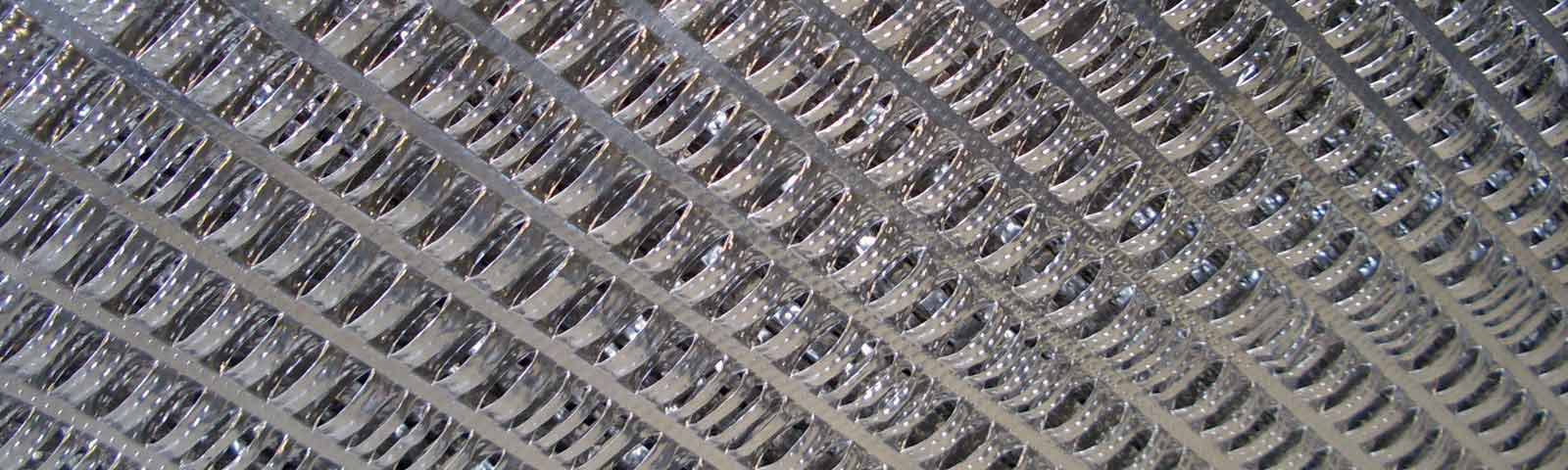

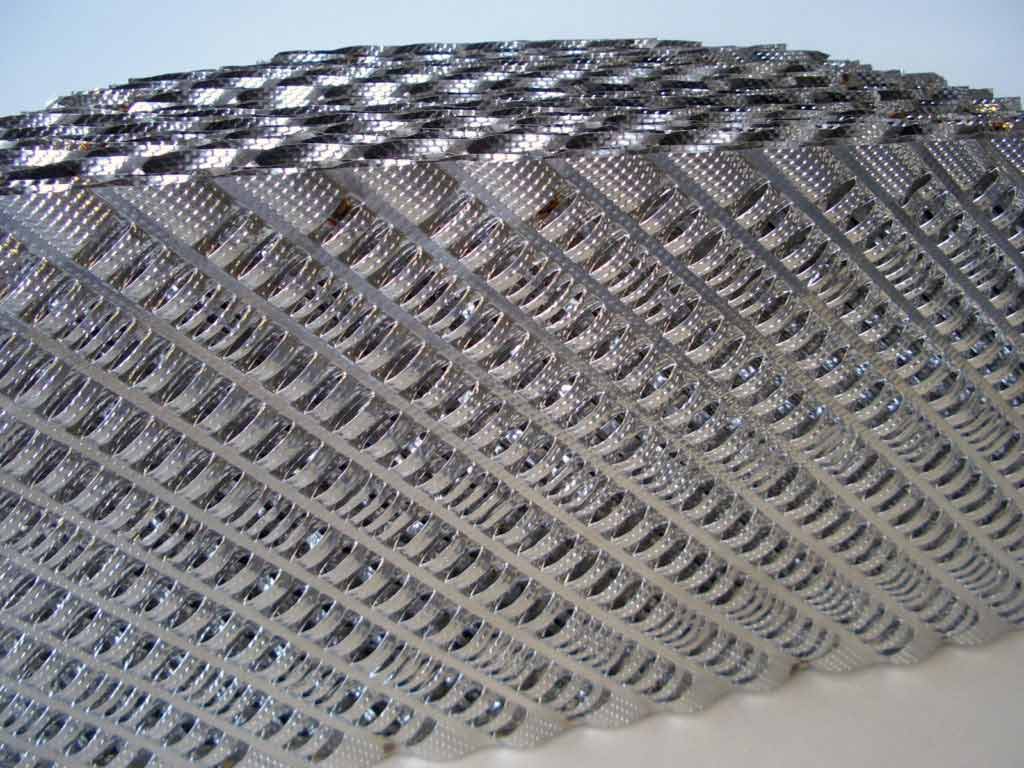

Packing material typically varies in size and shape and can consist of metal, graphite, plastic, clay, porcelain or ceramic. Beds can be stacked, dumped or randomly packed, to meet the separation requirements of the application. The large surface area provided by packed beds is the column’s key characteristic, due to the fact that as it increases there is more time for liquid-vapor to come in contact, which improves separation efficiency.

When liquid blend is fed into the column and heated, vapors rise and the liquid descends. The fluid that pools at the base of the column is then fed into a re-boiler that creates vapor, which re-enters the column. The vapor that rises through the column is fed into a condenser. It then is directed into a reflux drum, separating the overhead product stream, or distillate, from the reflux stream, which is then fed back into the distillation column.

Liquid flow must be carefully controlled in order to achieve cost and contact efficiency in packed bed columns. Packing material can also break due to thermal expansion or during the loading process. Overall, however, packed bed columns are well suited to thermally sensitive liquids, low-pressure operations, and corrosive substances — making them a popular distillation choice in a broad range of industrial applications.

Honiron Manufacturing is an industry-leading manufacturer of distillation columns. For more information or to speak with one of our qualified experts, contact us today.