Boilers are one of the most widely used pieces of equipment in industrial processes and come in a variety of forms.

Two of the most common boiler types are fire tube and water tube. Here is a brief overview of each.

Fire Tube Boilers

Fire tube boiler date back to the industrial revolution, where they were used in steam engines, both for locomotives and industrial plants. They work by circulating hot gas through tubes, which in turn run through a water tank. The water is heated and eventually turns into steam, which is then used to generate energy.

Fire tube boiler often have extensive maintenance requirements and are best suited for applications with lower pressures. In recent years, fire tube designs have become more compact and efficient, incorporating features like reverse flame to get the most out of the heat source.

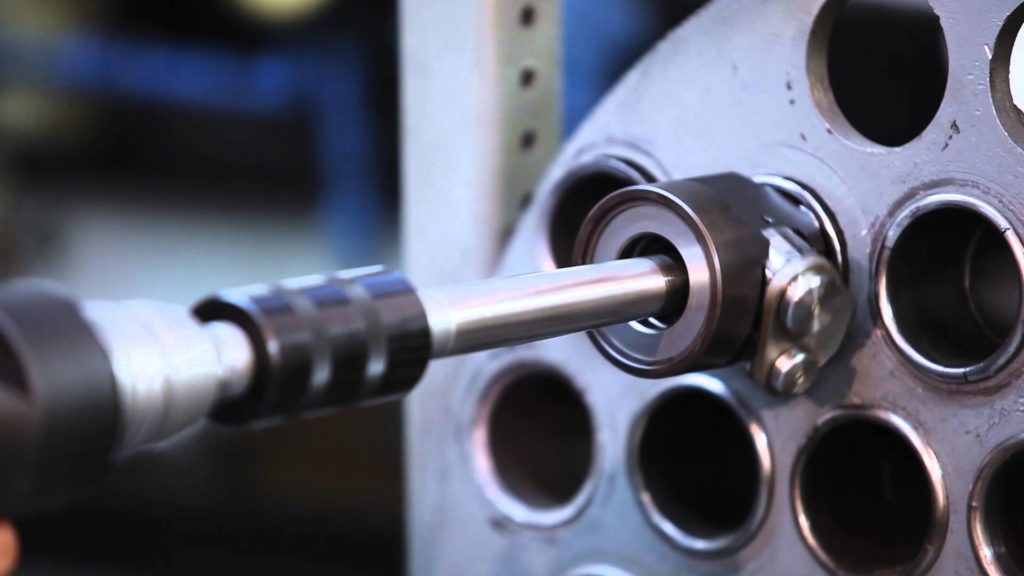

Water Tube Boilers

Unlike fire tube boiler, where the hot gas is circulated through tubes to heat water in a tank, water tube boilers involve running water through tubes surrounded by a heated tank.

These types of boiler are generally considered safer than fire tube designs and typically require less frequent maintenance. They also can be designed for larger capacities and recover quicker. Water tube boilers can operate at pressures up to 5000 psig. Additionally, when used with steam circulating super-heaters, they are capable of reaching much higher temperatures than fire tube boilers.

For these reasons, water tube boilers have become the most commonly used boiler type in the modern age. Their broad ranging applications include power generation, sugar production, and a variety of oil and gas, petrochemical, and refining processes.

For more information, please visit our homepage or contact us today.